SPM Machines

We are the leading Manufacturer & Supplier of Special purpose machines. Our product designed with accuracy, our range is highly acclaimed and appreciated amongst our clients for their optimum quality, precise engineering, high operational efficiency, longer functional life, enhanced durability, accurate designs and low maintenance.

Our machine Varieties are as follows –

we offer Conveyor for Food processing application, Automotive Conveyors, Transport Conveyors, Industrial Conveyors, Line Shaft Roller Conveyor and cleated belt conveyor. Conveyor systems play a crucial role in streamlining and optimizing material handling processes in numerous industries

Our Aluminium Workstations are designed to be lightweight, yet strong and durable, with high-quality materials and construction that ensure long-lasting performance. We offer a variety of workstation types, including bench workstations, assembly workstations, and packing workstations, each designed to meet the specific needs of your application.

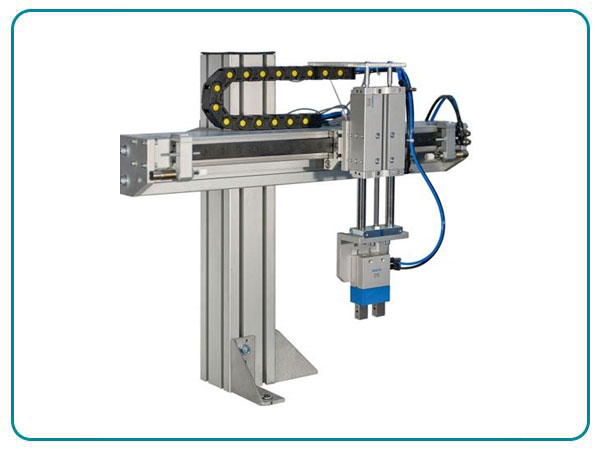

We design and make all types of pick and place machines. With optimum quality range and extremely rugged for every industry.

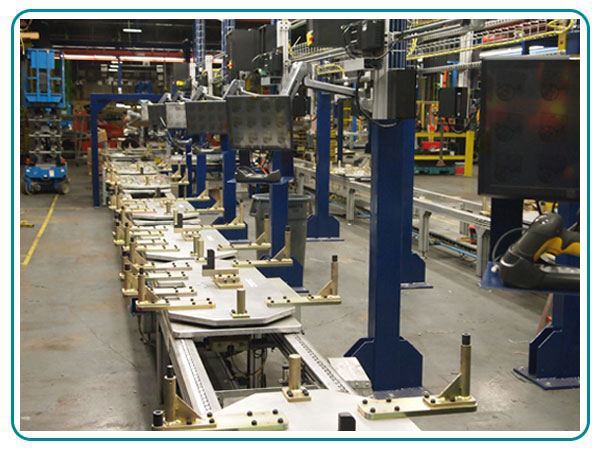

Provides a wide range of assembly line machines or equipment that are commonly used in large industrial sectors to assist the manufacturing or assembly process for performing some automatic tasks such as assembling components, packaging, testing or performing quality checks.

offering the best robotic assembly line that is used in large industrial applications for performing major tasks with great accuracy and without any human intervention or labour.

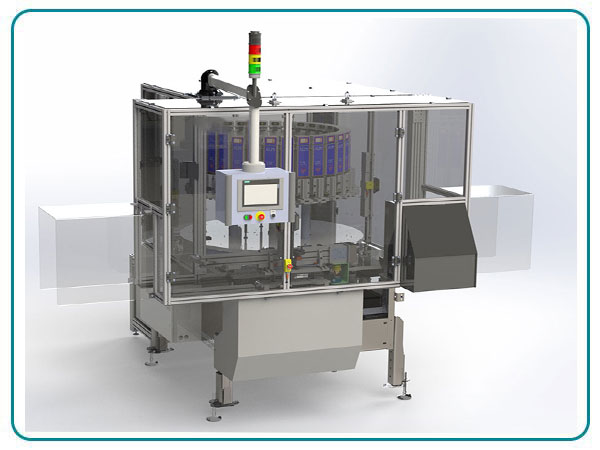

providing a highly demanding leak test machine that is primarily used for detecting, measuring and locating the leaks in the machines. As per the requirement, we manufacture these machines into various testing methods, such as differential leak testers, rotary leak testers and vacuum leak testers.

We are providing the best quality material handling system that is commonly used for improving the flow of materials, operational efficiency and reducing waste. This system is coordinated and operated by humans and machines and comes in manual, semi-automated and fully automated. These material handling machines or systems can be able to do multiple amounts of tasks.